Semiconductor and Electronics

DIRECT AND INDIRECT MATERIALS

Die Attach Film

Process Automation

- Wafer Dicing Attach Tape (DAF Tape, WBL)

- UV curing type

- Thermal curing type, high adhesive strength

- Expandable type

Die Attach Paste

We offer some of the most advanced Die Attach paste adhesives engineered to improve long-term reliability, rapid inline curing, long pot-life, viscosity and thixotropic control for fast automated dispensing and manufacturing.

Electrically Conductive Paste Adhesives

Electrically Conductive Paste Adhesives

-

- One or two part component

- Stress free-Substrate/component

- Large area die attach

- Solder replacement

- Ideal for mismatched CTE’s

- Designed to eliminate bleeding

- Moisture resistant

- Fine pitch

- Rapid curing

Electrically Conductive Paste Adhesives

-

- One or two part component

- Stress free-Substrate/component

- Large area die attach

- High Power Die Attach

- Diamond Filled (custom made)

- Fast curing

- Rapid curing

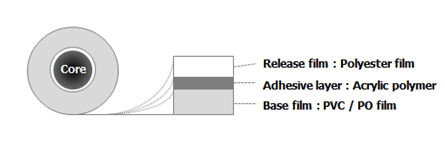

Dicing Tapes

Types of Dicing Adhesive Tape

- Wafer Dicing Tape

- UV or Non-UV uring type

- Improved back side chipping, contamination

- Expandable type

[table id=2 /]

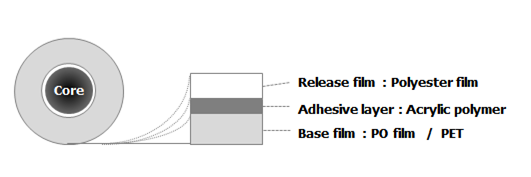

Backgrind Tapes

Types of Back Grind Adhesive Tape

- Wafer Back Grinding tape

- Improving TTV Value

- Prevent Dust and Wafer Penetration

- Absorbs Mechanical stress

[table id=3 /]

Package Dicing Adhesive Tapes

Types of Dicing Adhesive Tape

- Package Dicing tape

- UV curing type

- Improved back side chipping, contamination by water

- Higher Adhesive tape for Package Dicing Application

[table id=5 /]

Bonding Wire Product

Bare Metal Line Up

Gold Bonding Wire

| High Performance 4N (IU / UB) | Broad Bonding Window & High UPH |

| High Strength 4N (UL / UN) | Excellent Looping & T/C |

| 2N Gold (R/UP) | Excellent Reliability |

Copper Bonding Wire

| High ority Copper Wire (BC) | High Conductivity & Cost Advantage |

| Alloyed Copper Wire (CA) | Better Workability & Realibility for Automotive |

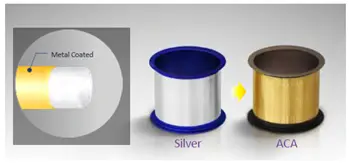

Silver Bonding Wire

| Ag > 96% Alloy Wire (SI) | High Conductivity |

| Ag 94 ~ 96% Alloy Wire (SN / SR) | High Reliability & Workability |

| Metal Coating Wire (ACA) | Gas Free Bonding & Low Cost than Gold |

Aluminum Bonding Wire

| Corrosion Resistant Aluminum Wire (AN) | Corrosion Resistance Excellent Clean Surface |

| Wide Properties Aluminum Wire (AH) | Stable Looping Performance Excellent Clean Surface |

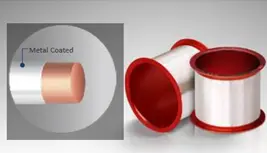

Metal Coated Copper (cu) Wire

[table id=6 /]

Heavy Aluminum (AI) Wire

[table id=8 /]