Semiconductor and Electronics

SOLDER PRODUCTS

- Demand for lead-free solder has increased dramatically since the 2006 restriction came into effect for leaded consumer electronics

- Ovitech partnership with Shenzen JF solder company in technology application and cost-effective premium quality solder ball, flux, paste, and nanopowder

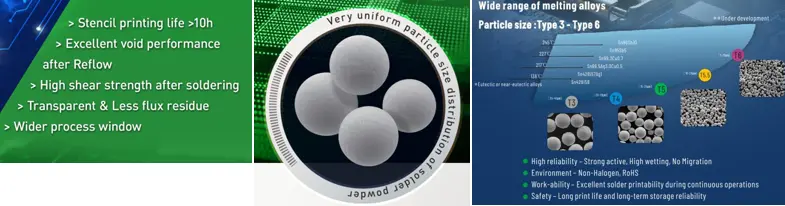

Cost Effective Premium Solder Ball

- Main elemental composition: Tin (Sn) 96.5, silver (Ag) 3.0, copper (Cu) 0.5;

- Alloy density: 7.4g/cm3 ( 20℃);

- Solid state to liquid state temperatures: 217℃~219℃;

- Solder Stable Temperature : 300℃+10℃/-0℃;

- Anti-oxidation properties

- Always remain silvery-white

- Phosphorus free

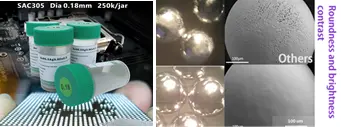

Highly Uniform (HU) Solder Paste for Mini Led

- High sphericity of tin powder & concentrated particle size

- Long stencil printing life (>10h)

- Good shear strength for solder joint and high reliability

- Low voids

- Excellent void performance after reflow

- Low and clear residue of solder paste flux. The residue and substrates metal do not change color or have an impact on the LED’s luminous quality after being placed in a constant temperature chamber at 40°C for 240 hours.

- High thermal and electrical conductivity, the thermal conductivity of SAC305 alloy is about 54W/ m·K.

- Good thixotropy, good dispersion, and the optimum viscosity needed for curing and printing

- Follow the recommended reflow profile parameter setting, it will benefit for soldering and reduce die tilt & die shift issue.

- The cost of curing solder paste is much lower than silver glue and Au80Sn20 alloy, and the curing process saves energy.

- The particle size is 5-15μm for No.6 powder, 2-12μm for No.7 powder

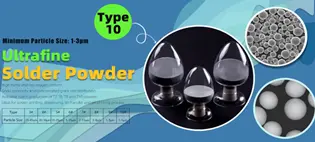

Ultrafine Solder Powder

[table id=10 /]

*Passed SGS test, RoHS, REACH and other Certifications

Low Alpha Solder Powder

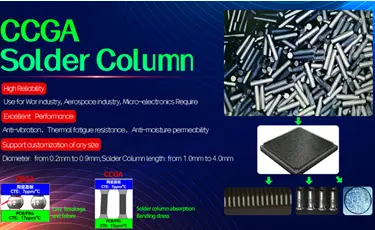

Column Grid Array and

Sn Columns

Cu Columns

Micro Coil Spring