Semiconductor and Electronics

TEMPORARY BONDING

Temporary Bonding

Ovitech and its partners has developed temporary materials and carrier. Traditional temporary bonding adhesives for wafer processing have always required a carrier to match carrier-device wafer CTE during the rigors of processing. By eliminating the traditional glass carrier or silicon wafer carrier, wafer per hour throughput is greatly increased.

To successfully enable wafer processing with disposable carrier the key is the innovative, molecularly engineered temporary bonding adhesive: highly conforming, stretchable, and flexible temporary bonding adhesive yet with high shear bonding strength and high-temperature stability.

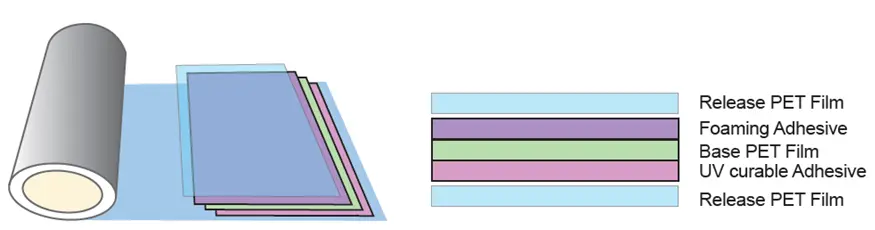

Heat-UV Release Tape (Hybrid Temporary Bonding Technology )

- Non residual molding release for panels up to 700mm

- Application for disposal carrier or double-sided adhesives for use with glass-wafer and steel carrier

- High temperature processing and molding up to 190°C

- UV flash release without residual on glass or PET UV transparent carriers

- Release adhesive layer is available from 20 to 200 µm in thickness for bumps and features of different heights and widths

- High shear bonding for molding stability

- Acid plating bath and water-based cleaning

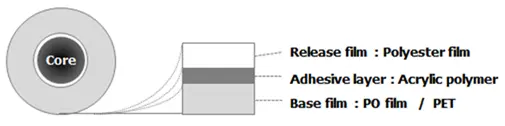

UV Release Tape

- UV flash release without residual on glass or PET UV transparent carriers

- Non residual molding release for panels up to 700mm

- High temperature processing and molding up to 210°C

- Release adhesive layer is available from 20 to 200 µm in thickness for bumps and features of different heights and widths

- High shear bonding for molding stability

- Acid plating bath and water-based cleaning

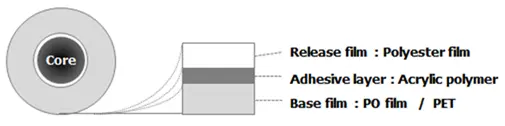

Heat Release Tape

- Non residual molding release for panels up to 700mm

- Application for disposal carrier or double-sided adhesives for use with glass-wafer and steel carrier

- High temperature processing and molding up to 210°C

- Release adhesive layer is available from 20 to 200 µm in thickness for bumps and features of different heights and widths

- High shear bonding for molding stability

- Acid plating bath and water-based cleaning